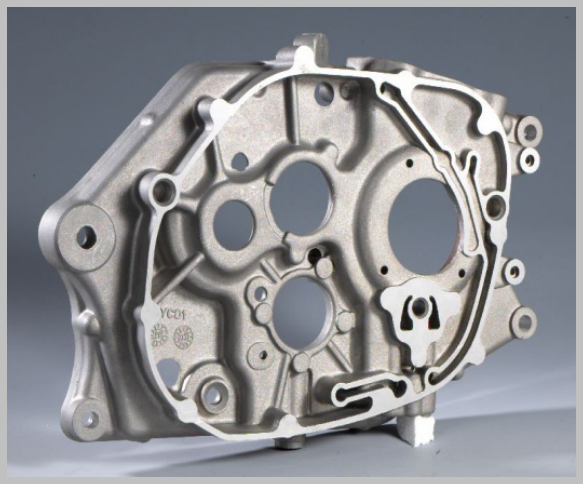

Main product:Die-casting,** moldi

The **hine **ponents die-casting **hine **ponents produced using modern science and technology, the use of **hine **ponents for the operation of the metal casting process.

When the **hine **ponents are used for die casting, the die casting effect is more perfect, the die casting size is more accurate, and has a better effect in actual production. In the actual production of engineering, various **hines and structures h**e been widely used. The **hine **ponents h**e their own specific functions and fixed shapes. The **hine **ponents also represent a part of the physical implementation of the system. The use of **hine **ponents for die casting is based on object-oriented technology and has a self-describing nature that can effectively integrate development environments with third-party software **hine **ponents. The use of mechanical **ponents for die-casting is relatively simple in terms of technology. **pared with other technologies, the die-casting surface of **hine **ponents is more even and the requirements for dimensional consistency are even higher. Some technical defects in the die casting process such as wear, erosion and the like occur. In addition, the storage environment of the **hine **ponents is also very important. Try to **oid being in an environment where the temperature changes too much. This is because thermal cracking occurs when the surface of the **hine **ponent is too large due to a temperature change. What's more, after using too many times, it will lead to thermal fatigue caused by defects on the surface of the **hine **ponents. As a result, the use effect of the **hine **ponents in the die casting process is affected.