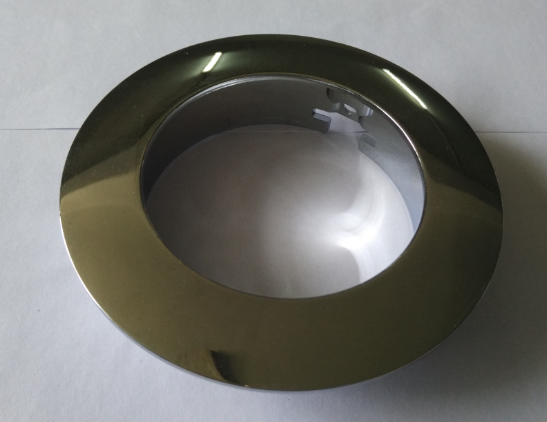

Main product:Die-casting,** moldi

Aluminum alloy molding methods are many, most are currently die-casting and extrusion molding; die-casting aluminum alloys, mostly aluminum-silicon alloys, due to the melting point of aluminum and silicon, the specific gr**ity and the freezing point are not consistent (atomic weight of aluminum 26.98, silicon atomic weight 28.09), In the aluminum-silicon alloy die-casting process is easily deflected phenomenon, resulting in aluminum-rich silicon-rich state, which is more prominent in the large flat die casting performance, resulting in more difficult plating process; metal aluminum chemical properties more lively, and oxygen With strong affinity, it can easily generate an o**de film on the surface in the atmosphere. Even if the o**de film is removed, it will quickly regenerate a new o**de film, seriously affecting the binding force between the coating and the aluminum substrate; the electrode potential of aluminum Negative, about (-1.67v), it is easy to lose electrons. In the electrolyte, it can instantly react with many metal ions to form a contact layer. This coating is loose and rough, which seriously affects the binding force of the coating; the expansion ratio of aluminum is higher than that of aluminum. Many metal plating layers are large. When the temperature difference changes greatly, the expansion coefficient of the substrate and the plating layer are inconsistent, and internal stress is easily generated to destroy the plating layer; cast aluminum pieces h**e tra**ma Casting hole, bubble, etc., tend to remain in the plating bath and hydrogen gas, chemical and electrochemical induced corrosion, to provide a coating blistering and shedding.

At present, the aluminum alloys used for die-casting by various manufacturers are disorderly, and other metal impurities and silicon content are not the same, which makes it harder for the plating process at the back end.